Key Points

- Machine learning control can provide benefit to many industrial problems through the provision of optimal and automated control policies to support system owners

- Forecast plant performance using advanced modelling techniques with adjustable control strategies

- Combine digital twin technology with optimisation techniques to discover new and improved control strategies to boost plant efficiency

- Implement risk free control upgrades through a human-in-the-loop technology by providing system experts with a digital understudy

Optimising performance of industrial plants requires continuous expert tuning of numerous controls and consideration of multiple interacting performance metrics. Machine learning algorithms can be trained to learn complex behaviours relating to system performance, and then be exploited with optimisation algorithms to automatically suggest control strategies to optimise plant performance – thereby reducing operational cost, increasing plant efficiency and minimising harmful emissions.

This process is known as machine learning control and has many applications across industry such as:

- Optimising yield in a production setting

- Optimal control of wind turbine pitch angle

- Optimising product quality in manufacturing

- Minimising energy use in energy intensive processes

- Irrigation control in agriculture

- Optimisation of wastewater treatment for reduced odour

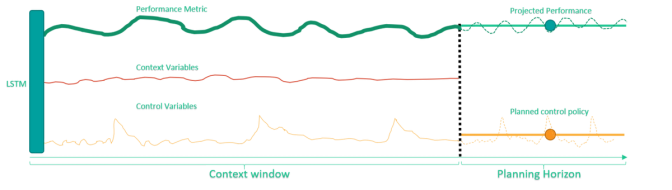

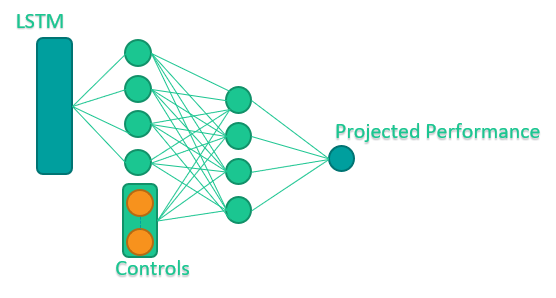

Successful implementation relies on the development of a machine learning model trained to predict process performance, given inputs defining various control policies and relevant contextual information, as seen in Figure 1. This model can be expanded with an optimisation process allowing for the suggestion of control sweet spots to optimise system performance and act as a digital twin.

Implemented in real time continuous systems, this approach can simplify control processes and find rewarding system optimisations in varying environmental conditions.

AI Support for Plant Controllers

Plant controllers have a huge responsibility in the operation of industrial systems. They must govern an often vast non-linear and time dependent system to ensure that multiple performance targets are met. This could involve hitting a manufacturing quality threshold, minimising emissions below a target allowance, limit waste to within available storage space, all while ensuring power usage is within tolerable limits. This multi-dimensional, multi-target optimisation problem must be solved continuously to a degree that allows the plant to maintain healthy margins.

By applying machine learning control best practices to such industrial optimisation problems, the pressure on plant controllers can be alleviated. A performance forecasting agent deployed along side a suitable optimisation process can provide control policies to continually optimise performance. The automatically suggested control policies provide a robust and informed second opinion on control strategy, enabling decentralised knowledge requirements, reduced risk and reduced reliance on system controllers. The optimisation step is also likely to find control sweet spots, unlocking a simultaneous step change in performance.

System control becomes more difficult during periods of volatile uncontrollable conditions. Take for an example the control of crop irrigation during periods of extreme weather. The ability for machine learning control frameworks to consider relevant contextual information such as environmental conditions within its predictions allows the automatic controller to be robust and consistent during periods where plant controllers can be less certain, enabling increased confidence and maintained performance during difficult times. The nature of these uncontrollable factors is dependent on the process. Other examples may include quality of input resources in manufacturing, ambient temperature and other weather conditions in agriculture, electricity prices in heavy industry and changes to policy around emissions thresholds. By also reviewing all relevant and quantifiable contextual information an ML enabled automatic controller can add further support to the system expert and offer robust advice irrespective of uncontrollable external factors.

Multiple Metrics and Many Controls

As discussed above, industrial processes are almost always multi-dimensional and non-linear. Machine learning control can easily handle many controls within its performance prediction engine, the only concern would be the speed of the optimisation stage when many controls are involved in a system with high frequency input. This may make deployment more difficult without providing expensive computing power to the algorithm.

It is important to recognise the nature of each control parameter. Some controls are likely to be fully continuous such as a target temperature while others could be binary or categorical. For continuous variables there is likely to be fixed limits or boundaries of allowable values that can be taken, if so, the optimisation algorithm needs to be well constrained to take this into account.

Having to balance trade-offs in performance such as the interaction between power draw and production rate in manufacturing is perhaps the most significant difficulty operators face when optimising their systems. Ada Mode handled this aspect of the problem within the optimisation of a biogas upgrade plant from the anaerobic digestion industry. The plant’s performance metric was a function of gas quality, emissions, and power draw; the three of which were reduced to a single cost of operation within the utility function. This simplified the multi-objective optimisation problem allowing for the use of standard optimisation approaches, such as evolutionary algorithms, Bayesian hyperparameter optimisation or particle swarm optimisation.

By using expert knowledge to resolve the performance metric to a univariate problem allows for this process to become highly adaptable to multiple industrial problems. Example optimisation targets include costs, emissions, waste, output quality, a function of multiple objectives and more.

Limitations

AI will likely never replace real human experts. We can train the performance prediction engine on as much operational history as possible, but there will remain a chance that the AI will get things wrong particularly when facing conditions not seen in training. Novel system behaviour such as faulty input materials in manufacturing, record breaking temperatures or workforce restrictions can have an unforeseeable effect on a related systems performance. Machine learning algorithms cannot be expected to perform when extrapolating to new conditions.

Enforcing restrictions on the optimal control strategies can be complex. Optimisation cheating can result in the suggestion of unrealistic or impossible control strategies if the optimisation problem is not constrained properly or the policies are not defined correctly within the predictive model inputs. This issue can be avoided if the industrial process is well defined and the highest level of control data is available.

Applications in Anaerobic Digestion

Ada Mode have applied machine learning control to optimise the performance of a biogas upgrade system for an anaerobic digestion plant. The plant is responsible for processing raw biogas into biomethane and refining it to meet grid standards. Potential savings of the approach in testing reach £95,000 per year and include reductions in ~5,000kg of emitted methane to the atmosphere.